Idan kana son yin bene mai kyau wanda ba ya jure lalacewa (ko bene mai inganci na warkarwa), dole ne ka yi aiki da ƙarfin tushen siminti, musamman ma dai dai. Bene mai kyau wanda ba ya jure lalacewa ba yana da alaƙa da ingancin kayan da ke jure lalacewa. Ana buƙatar ƙasa mai kyau ta tushe. Wannan takarda tana da nufin samar maka da mafi cikakken kuma cikakke na'urar daidaita siminti da fasahar bene mai jure lalacewa. Abubuwan da ke ƙasa sune hanyoyin gini da Shanghai Jiezhou Engineering & Mechanism Co., Ltd. ta taƙaita bisa ga shekaru da yawa na ƙwarewar masana'antu. Don bayaninka.

Tsarin gini: maganin kwas ɗin tushe → saitin tsarin ajiya → ciyar da siminti → injin daidaita laser, girgiza da matsewa → yaɗa tarin ƙarfe → cirewar kalanda da cire slurry → gogewa → shayar da ruwa da warkarwa → yanke haɗin gwiwa na inji da grouting.

Hoton ginin laser scrap

Maganin tushe

1. Da farko, za a cire sharar da ke kan hanyar tushe kuma ba za a sami wasu busassun abubuwa a saman hanyar tushe ba.

2. A sassaka ɓangaren saman da ke fitowa daga ciki domin ya zama daidai da girman saman. A duba ko faɗin layin tushe ya cika ƙa'idar da ke tsakanin ± 2cm daga tsayin ƙira don tabbatar da kauri na siminti.

Saitunan samfuri

Da farko, bisa ga matsayin ginshiƙin ƙarfe na dukkan masana'antar, buƙatun ƙira, shirye-shiryen aikin, alkiblar tafiyar abin hawa da halayen ginin kayan aikin daidaita kayan aiki, an tsara tsarin zubar da gini mai inganci. Za a sanya aikin tsari mai ƙarfi a yankin gini. Aikin tsari zai zama aikin tsari na musamman da aka yi da ƙarfe mai tashoshi, kuma za a daidaita buɗewar saman aikin tsari don ya zama mai faɗi da daidaito a ciki da waje.

Saita layin zamiya

Bayan an gina tsarin ginin, za a rufe yankin ginin da fim ɗin filastik don raba tushen hanyar daga saman siminti don samar da layin zamiya.

Ramin ƙarfafawa mai ɗaurewa

1. Za a sarrafa ragar ƙarfafawa ta hanyar haɗa ta tsakiya da kuma haɗa ta a wurin, sannan a kai ta wurin da aka tsara don tarawa bayan ɗaurewa. Ya kamata saman ƙarfafawa ya kasance mai tsabta, babu datti, tsatsa, da sauransu don tabbatar da ingancin kayan aiki. Za a ɗaure ragar ƙarfafawa gaba ɗaya, kuma tazara da girmansa za su cika buƙatun ƙira da ƙayyadaddun bayanai. Bayan ɗaurewa, duba ragar ƙarfafawa don ganin ko layin kariya ya isa, ko ɗaurewar ta yi ƙarfi kuma ko akwai sassauƙa.

2. Kafin a zuba siminti, ma'aikata za su sanya shi a wurin da aka ƙayyade. Girman ragar ƙarfafawa shine 3M × 3m.

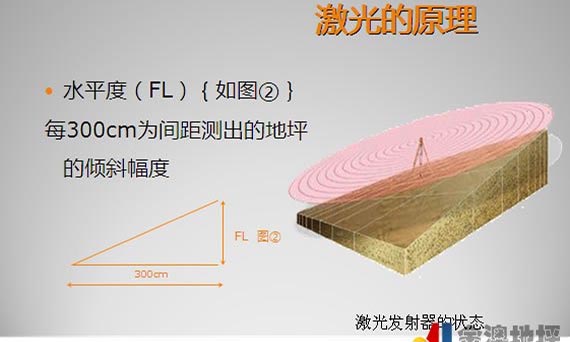

Na'urar daidaita laser

Kafin a zuba siminti, a gyara injin daidaita laser. A gyara kuma a daidaita na'urar watsa laser, sannan a daidaita matakin da tsayin kan daidaita simintin bisa ga siginar da aka watsa don ya yi daidai da tsayin ƙasan simintin. A lokaci guda, a daidaita bambancin tsayi a ƙarshen biyu na kan daidaita a cikin 0.5mm. Kafin a yi babban gini, da farko a yi amfani da kayan aiki don gwaji a samar da shi kuma a duba don tabbatar da cewa babu kuskure.

Zuba siminti

1. Za a yi amfani da simintin kasuwanci. Aikin simintin kasuwanci zai cika buƙatun takamaiman bayanai, kuma za a sarrafa faduwar simintin a cikin tsarin aiki a 160-180mm.

2. Za a yi siminti daga ƙarshe a cikin tsari mai kyau. Idan aka zuba cakuda siminti a cikin aikin, za a tattara kayan a hankali kuma a hankali, kuma kauri na kama-da-wane zai kasance kusan 2cm sama da aikin. Idan ya cancanta, za a rage ko ƙara kayan, kuma sassan tsaye da na kwance za su cika buƙatun. Za a yi simintin a kai a kai ba tare da katsewa ba.

3. Bayan an zuba simintin, za a daidaita tarin simintin da hannu a cikin ingantaccen kewayon hannun na'urar daidaita simintin, sannan a kammala girgiza, matsewa da daidaita simintin a lokaci guda tare da na'urar daidaita simintin laser. A cikin tsarin daidaita simintin, ɗauki alkibla ɗaya a matsayin ƙa'ida, sannan a kwanta daga ciki zuwa waje mataki-mataki.

4. Wuraren da ba za a iya yin aikin injiniya ba, kamar kusurwoyi da ginshiƙan ƙarfe, za a matse su a daidaita su da hannu.

Sa resistant bene gini

Kafin a fara saita siminti, za a yi amfani da faifan diski don yin liƙa har sai an fitar da slurry ɗin, kuma mai tauri zai bazu ko'ina a saman simintin. Bayan mai tauri ya sha ruwa, sai a fara niƙa; Bayan niƙa mai kauri, za a bazu layin tauri na biyu, kuma adadin kayan zai zama 1/3 na tsarin da ya gabata. Za a yi niƙa mai kauri yayin niƙa, kuma ba a yarda a rasa niƙa ba.

Matsewa da gogewa da kuma goge trowel

1. Bayan an daidaita simintin laser, za a ɗaga simintin a gama da trowel kafin da kuma bayan saitin farko. Za a yi aikin troweling na disc nicker sau da yawa bisa ga taurarewar Layer na saman. Za a daidaita saurin aiki na troweling na inji daidai gwargwado bisa ga taurarewar ƙasan siminti, kuma za a yi aikin troweling na inji a tsaye da kwance.

2. Kafin a gama saitawa, a maye gurbin faifan niƙa a matsayin ruwan wuka, sannan a daidaita kusurwar niƙa da gogewa. Gabaɗaya, aikin gogewa ya fi sau biyu don sanya mai sheƙi na ƙasa ya zama iri ɗaya.

Ragewa:Za a yanke haɗin gwiwa a cikin lokaci 2-3D bayan an gina layin saman da ba ya jure lalacewa. Za a yi amfani da yanke danshi don yanke haɗin gwiwa, mai kauri na 5cm da zurfin da ba kasa da 1/3 na kauri na siminti ba. Dinkin yankewa zai kasance madaidaiciya kuma kyakkyawa.

Warkewa: Bayan an goge simintin, sai a rufe shi da fim sannan a shayar da shi don ya warke. A lokacin da aka goge shi, lokacin da ƙarfin simintin saman filin bai kai 1.2MPa ba, kada kowa ya yi tafiya a kai.

Caulking

1. Bayan an gama gyaran bene na tsawon makonni biyu, a tsaftace wurin yanke kayan sosai sannan a cire duk wani ƙura da ya lalace a wurin yanke kayan.

2. Za a yi amfani da manne mai polyurethane mai ɗorewa da kuma saurin warkarwa don cike haɗin da ke raguwa.

Matakan sarrafawa

1. Dole ne kayan da aka yi amfani da su a wurin su kasance ƙarƙashin karɓar wurin, kuma a ajiye su a wurin da aka ƙayyade bayan an karɓi wurin. Lura cewa kayan da ke da buƙatun hana ruwa dole ne su ɗauki matakan da suka dace game da danshi da ruwan sama.

2. Samar da kwararrun ma'aikatan gudanar da gini da kuma kwararrun masu gudanar da gini. Kafin a fara gini, za a tsara ma'aikatan da suka dace domin gudanar da bayanai kan yadda ake amfani da injunan gini da kayan aiki yadda ya kamata da kuma kula da muhimman hanyoyin aiki, domin tabbatar da cewa ma'aikatan gini sun kware a gudanar da kowane aiki.

3. Injinan gini da kayan aikin za su cika buƙatun, su kasance cikin kyakkyawan yanayi, sannan su shirya wasu kayan aiki masu mahimmanci.

4. Ya kamata a kiyaye muhallin ginin wurin da tsafta domin hana ƙura da sauran busassun abubuwa su gurɓata ƙasa.

5. Za a cire aljihunan, shara da sauran kayan sharar da aka bari a wurin kowace rana domin tabbatar da cewa an share wurin bayan aiki. Idan akwai kayan sharar musamman, hanyar maganin za ta yi daidai da buƙatun maganin kayan musamman.

A ƙarshe, baya ga bin ƙa'idodin da ke sama sosai, kyakkyawan bene mai jure lalacewa yana buƙatar haɗin kai da haɗin gwiwa tsakanin siminti da bene mai jure lalacewa.

An kafa kamfanin Shanghai Jiezhou Engineering & Mechanism Co., Ltd a shekarar 1983, kuma ya mayar da hankali kan bincike da ci gaba, samarwa da sayar da injuna a fannin benen siminti. Injin laser screed, trowel na wutar lantarki, injin yankewa, injin dinki, injin dinki da sauran injuna suna amfani da sabuwar fasahar kuma abokan ciniki suna yaba musu sosai.

Tana da abokan ciniki a ƙasashe sama da 100 a faɗin duniya kuma jagora ce a masana'antar. Idan kuna da wasu tambayoyi, za ku iya kiran DYNAMIC, kuma za mu yi muku hidima da zuciya ɗaya!

Lokacin Saƙo: Agusta-24-2022